Intelligence Equipment

Handao Tech Honored Product

Tack Welding System-TUBE ASSEMB S8O

Achieve precise positioning, docking, and spot welding of tubes and rotary connectors using a combination of robotics and machine vision. It achieves production cycle time of up to 3 minutes per piece and can handle high-precision, high-quality welding for thousands of different tube configurations.

Product Features

Handao Tech Honored Product

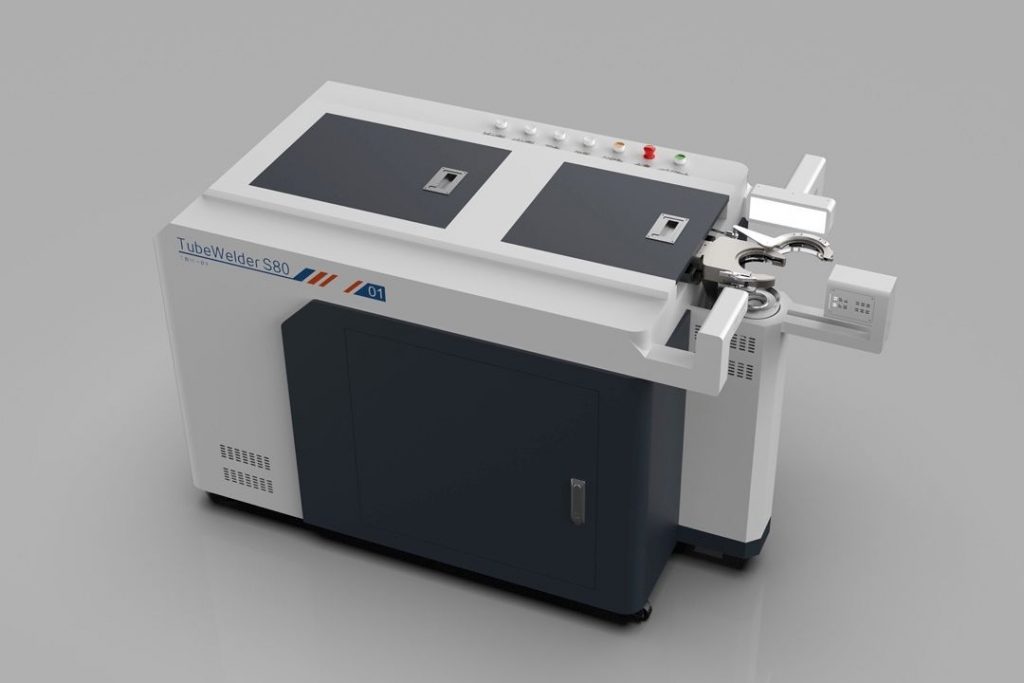

Orbit Welding System – TUBE WELDER S8O

Equipped with loading and unloading robots, dedicated intelligent weld seam sensors, and an automatic oribital welding machine, it is specialized for fully automated digital oribital welding of aerospace-grade tube systems. It achieves cycle time for batch production is 3 minutes per piece.

Product Features

Smart Manufacturing System

- Advanced Planning and Scheduling (APS)

- Supply Chain Management System (SCMS)

- Best Practices for Systems Integration

Advanced Manufacturing Process

- Metrology, chemical, laser, welding

- Heat treatment

Component Repair Development

- Cleaning

- Joining

- Machining

- Inspection

Material Testing & Analysis

- Engine component failure analysis

- Oil filter & metal chips analysis (CNAS-accredited)